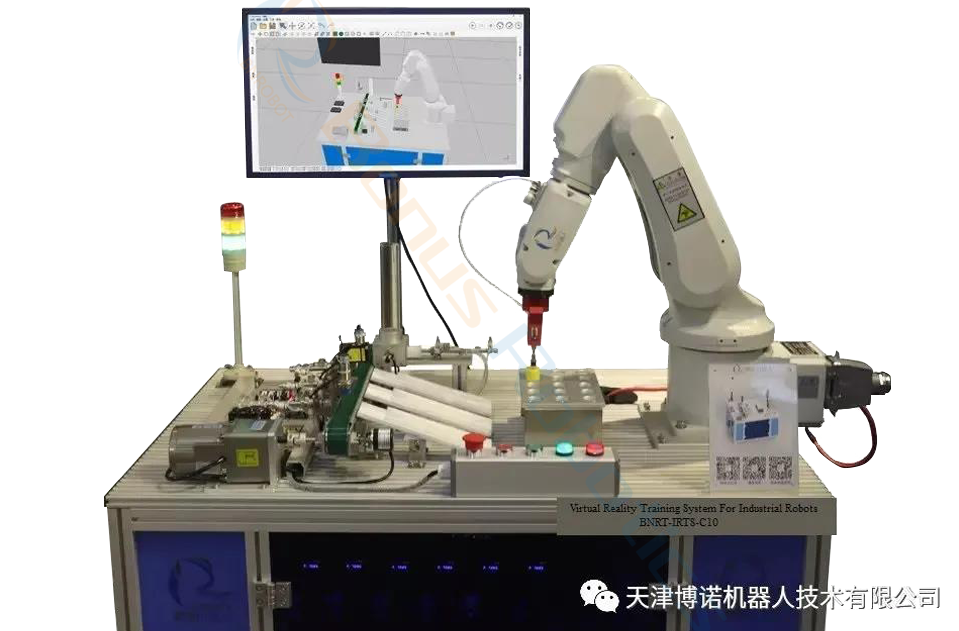

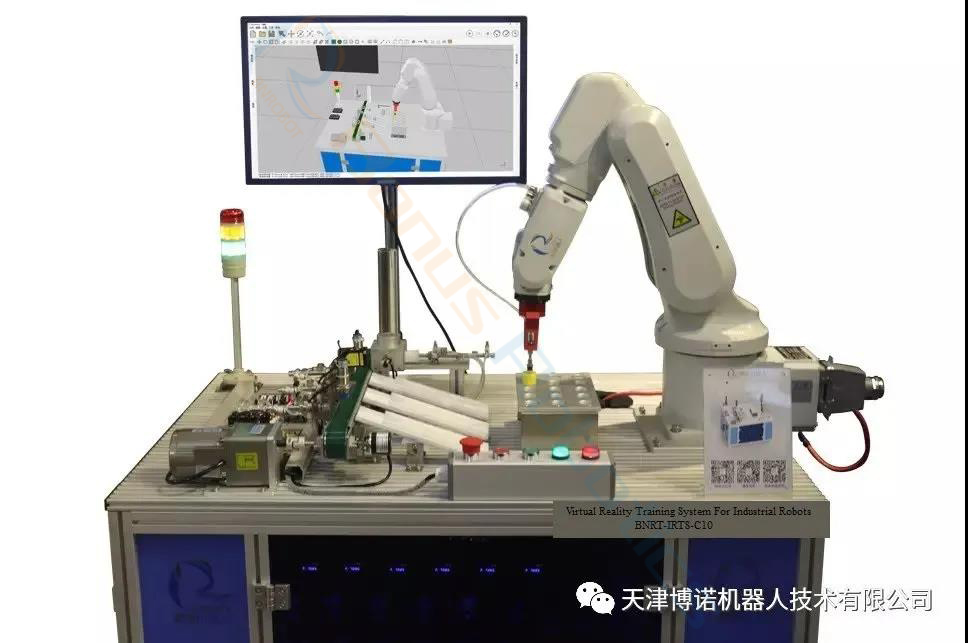

Function Overview

IRobotSIM is aproduction line analysis and planning software with independent intellectual property rights developed by Bonus Robot in conjunction with anumber of scientific research units for 5 years. IRobotSIM software simulates robots and manufacturing processes in a Simulation environment to realistically simulate the motion and Rhythm of the production line, and realize analysis, and planning of intelligent manufacturing production line. Has a rich 3D equipment library to support user model import customized, physical, and sensor simulation. It supports robot offline programming, convenient drag operation, and excellent simulation effects for large simulations, powerful API and digital twin development functions

Etc. IRobotSIM is suitable for enterprise intelligent manufacturing production line planning and college production line design learning. Itreduces security risks, saves money and improves efficiency.

Product Characteristics

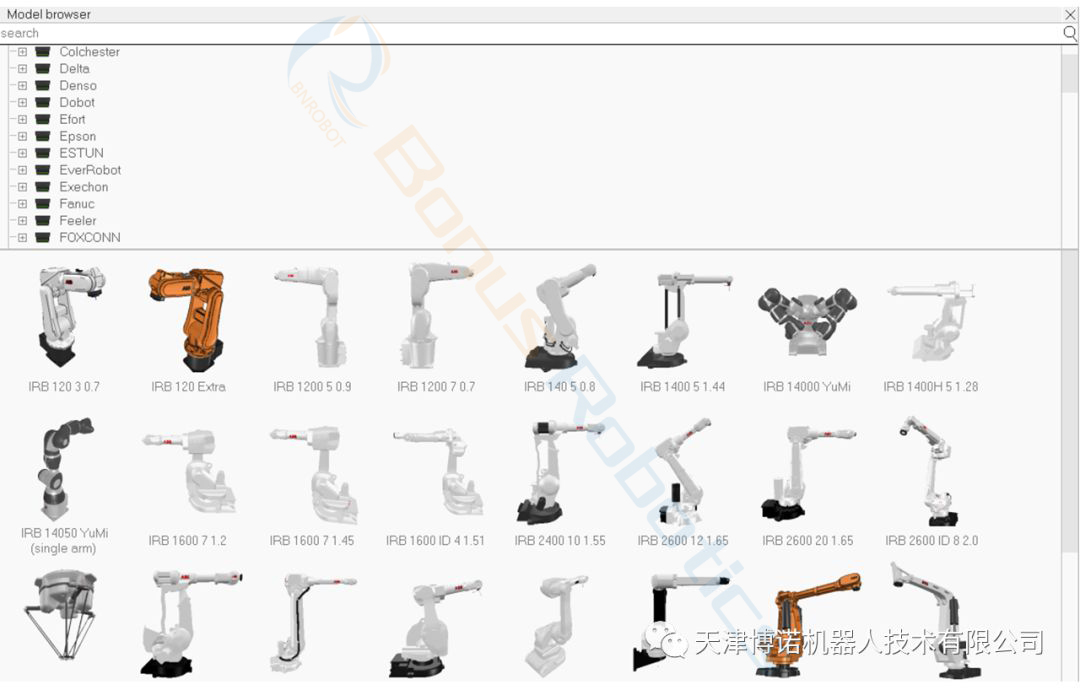

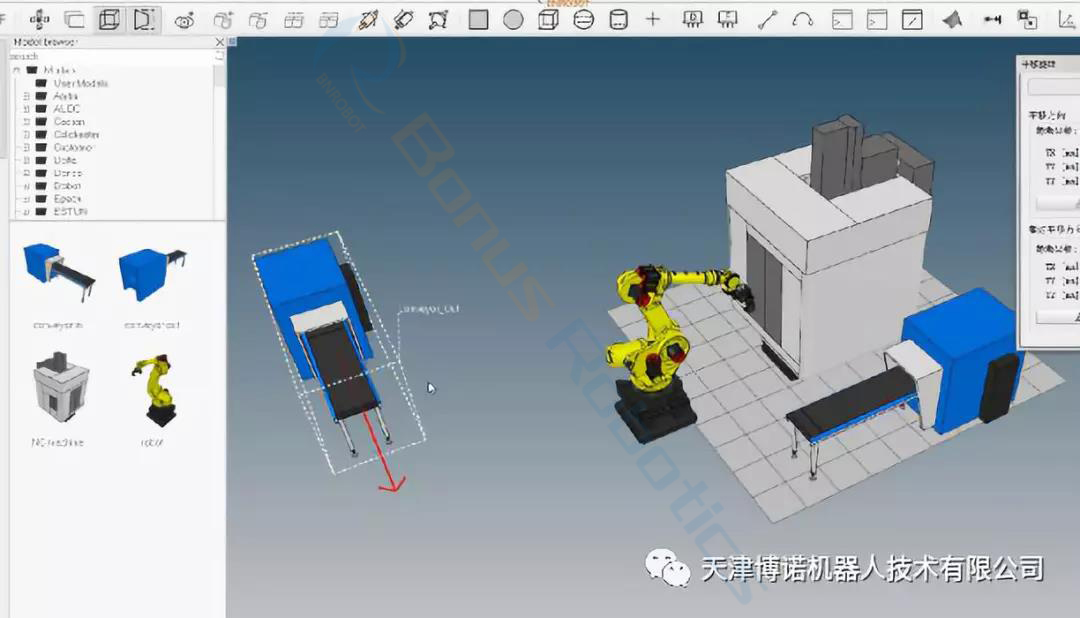

1. Complete 3D equipment library:

IRobotSIMhas

a complete robot model library, which supports most branded robotson

themarket,such as ABB,KUKA,Fanuc,etc. It also providesa large number of

production line components to support the simulation ofproduction lines in

large scenes.During the construction,dragging and simulation of large

simulations, the interface can run smoothly.

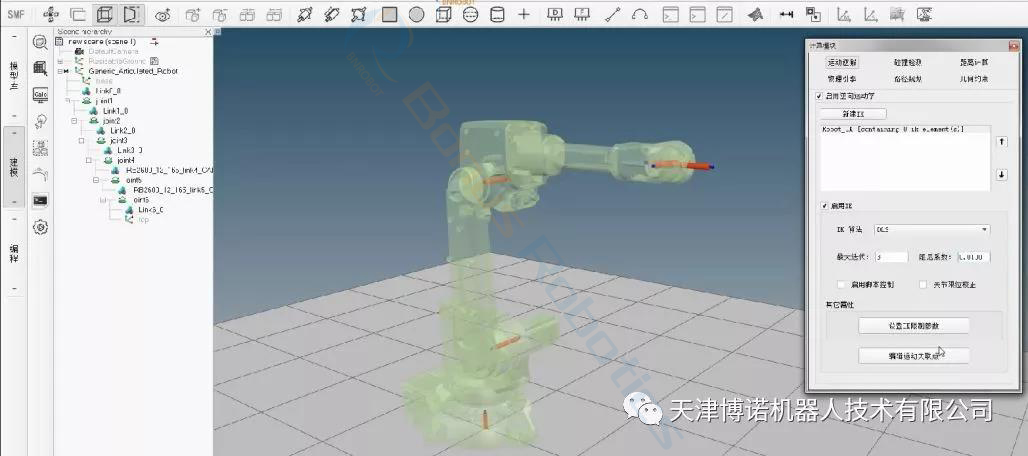

2. Custom model creation function

CAD

datacan be imported from the outside. Non-standard model components can be

made. New axis joints can be created,and axis joint chains can be constructed.

Andthe kinematic forward and inverse solution calculation can be added to the

robot.

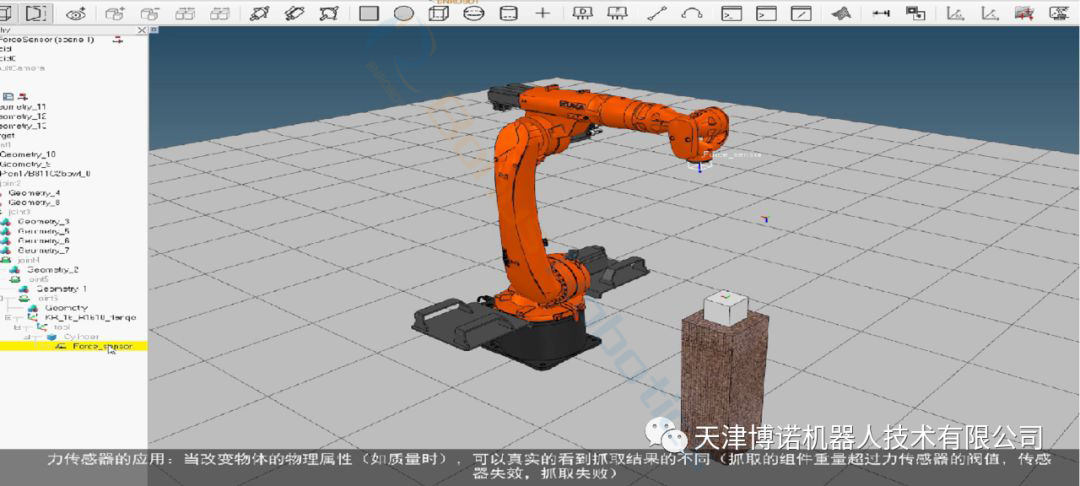

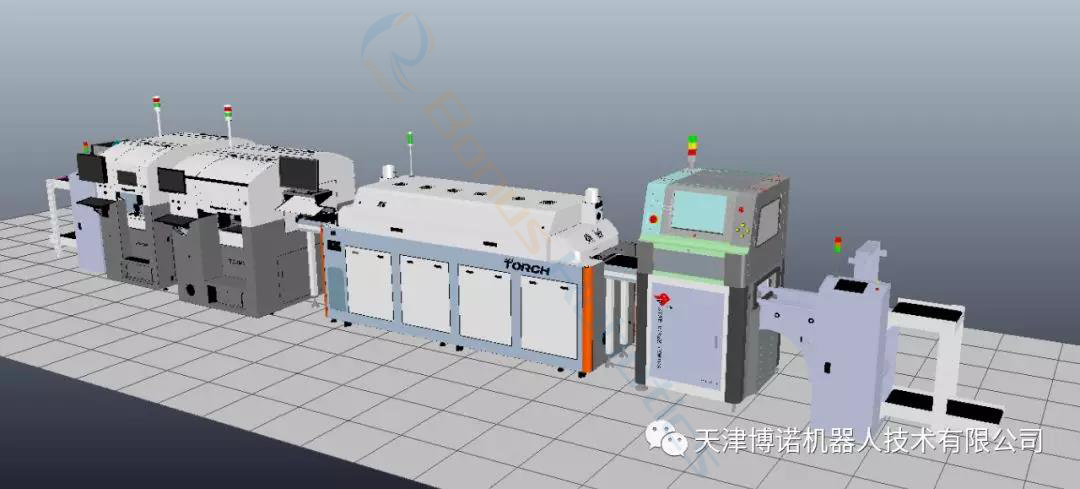

3.Physical property simulation function

With a physical engine,you can set and modify the physical and dynamic properties of components,create a virtual environment containing physical laws,and simulate physical phenomena in real life,suchas gravity, elastic collisions, etc.Simulation of various realistic physical and dynamic properties of moving objects such asdensity,mass,speed,acceleration,rotational angular velocity,and impulse.In the motion simulation rendering collision,friction, and force,properties can get different motion effects for different types of dynamic.

4.Sensor simulation function

IRobotSIMcan simulate a variety of sensor functions,suchas:

Forcesensor:can measure the force and torque ofthe motor;

Visionsensor:able to react to light,color, and pictures in space;

Distancesensor:accurately

detect an object within thedetection range.

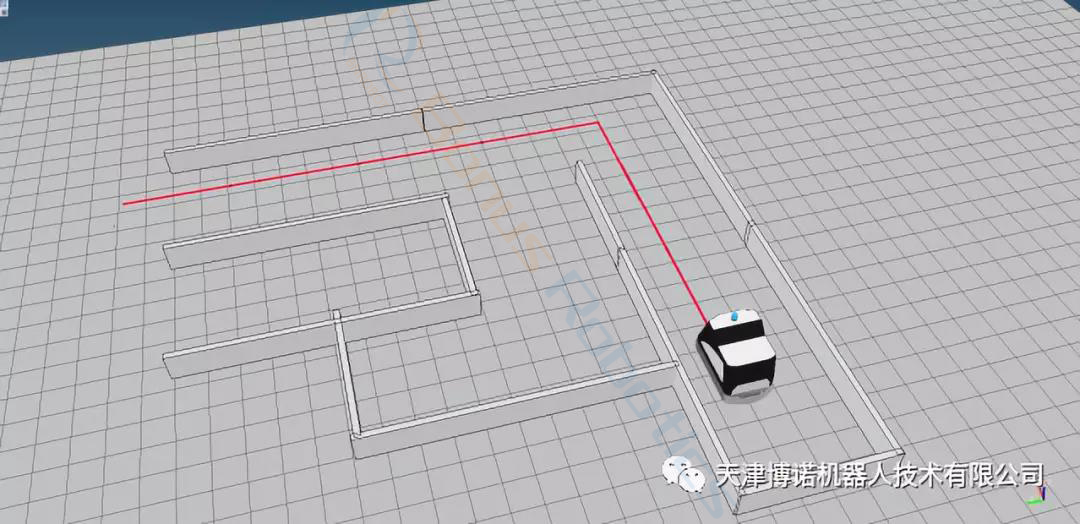

5.Rich computing modules

The

software includes the following calculation modules:collision detection

module,minimum distance calculation module,inverse solution mode calculation

module,geometric constraint solution module,dynamics module, and path planning

module; so that the simulated robot can obtain the function automatic obstacle

avoidance and path finding.

5.Efficiency calculation module

It

cancalculate the total amount of the robotwork for a fixed period and perform

efficiency calculations, and analyze the cost-effectiveness of different

parameters and layout schemes,single station equipment,andfull line capacity.

6.Convenient drag operation

It

cancalculate the total amount of the robot work for a fixed period and perform

efficiency calculations, and analyze the cost-effectiveness of different

parameters and layout schemes,single station equipment,andfull line capacity.

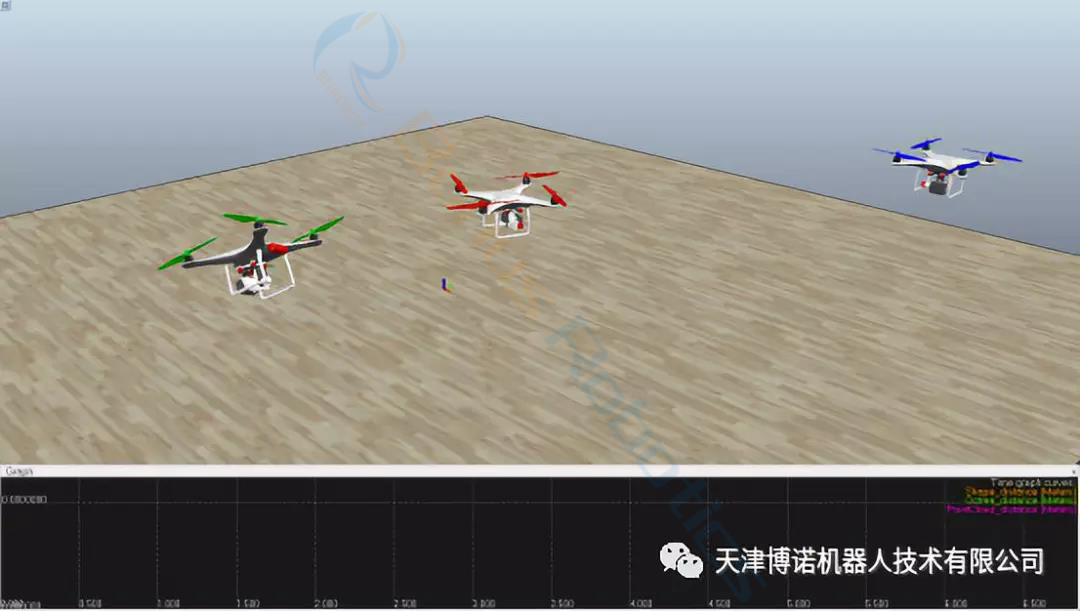

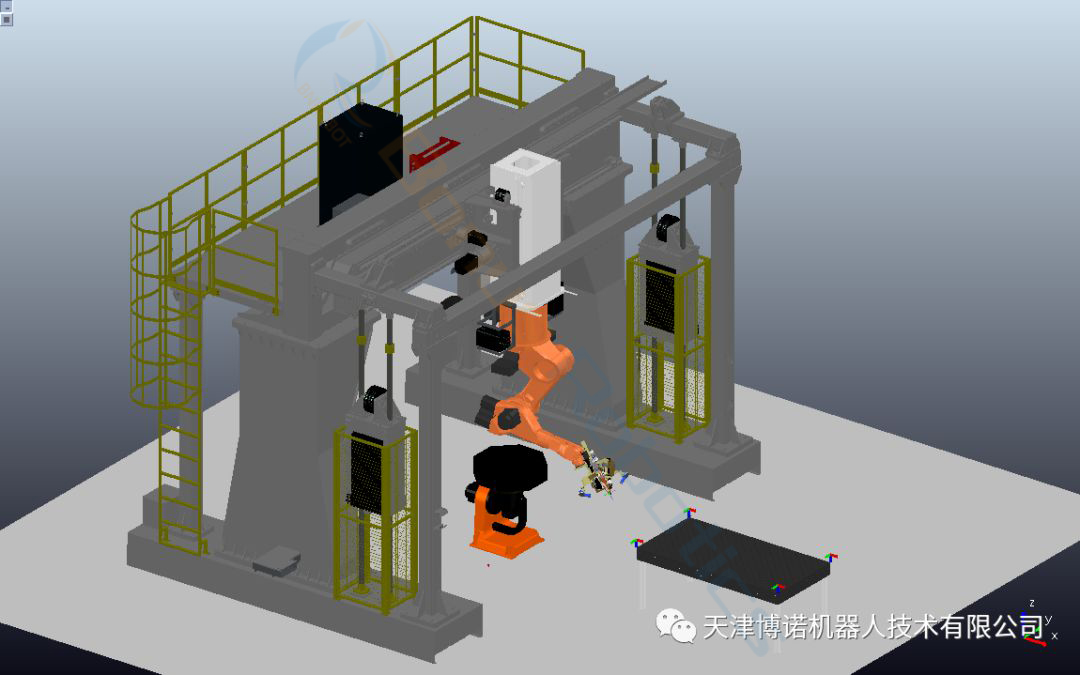

7.Robot simulation function

Using

the built-in inverse solution module. Through the interactive computer graphics

technology and robotics theory,the robot's geometric figures are generated in

the computer and displayed in three dimensions to determine the dynamic changes

of the robot's body and working environment.

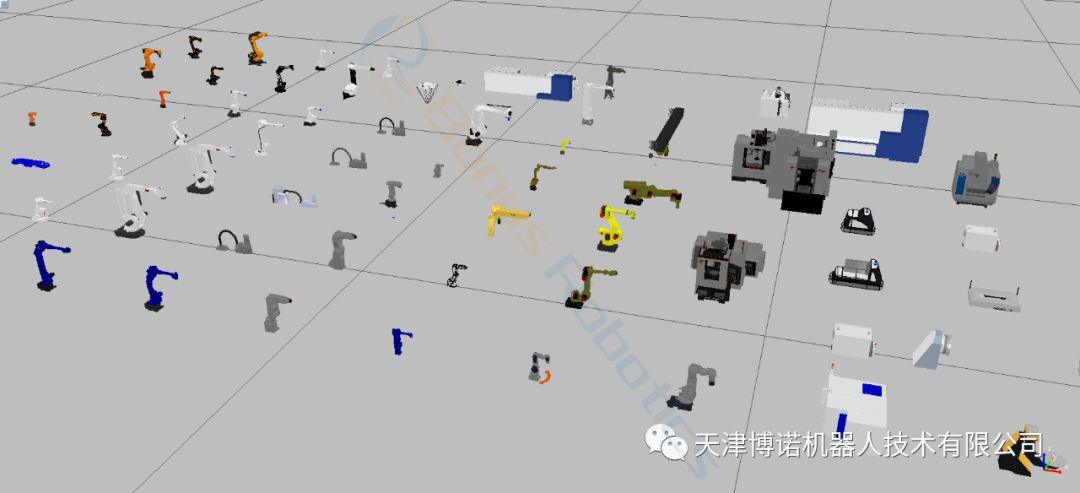

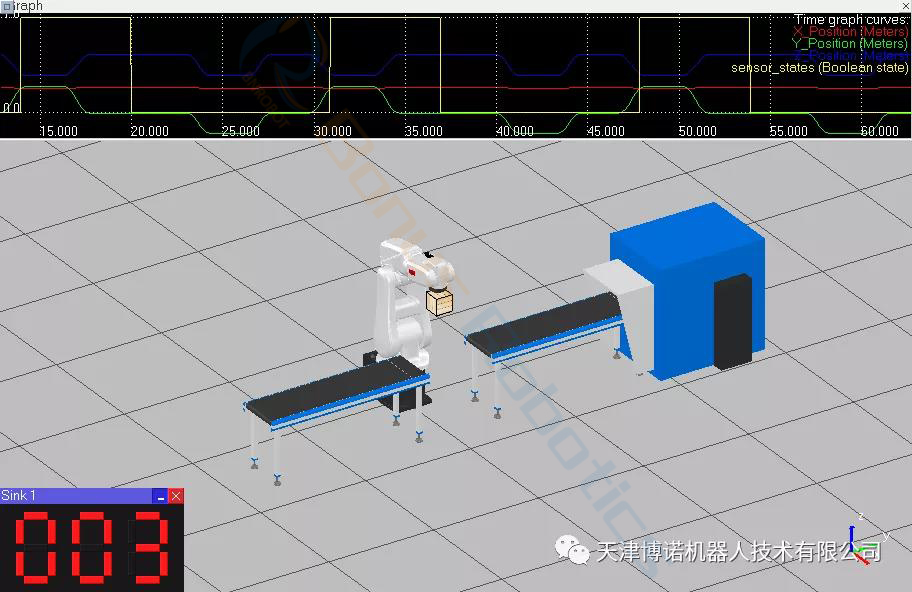

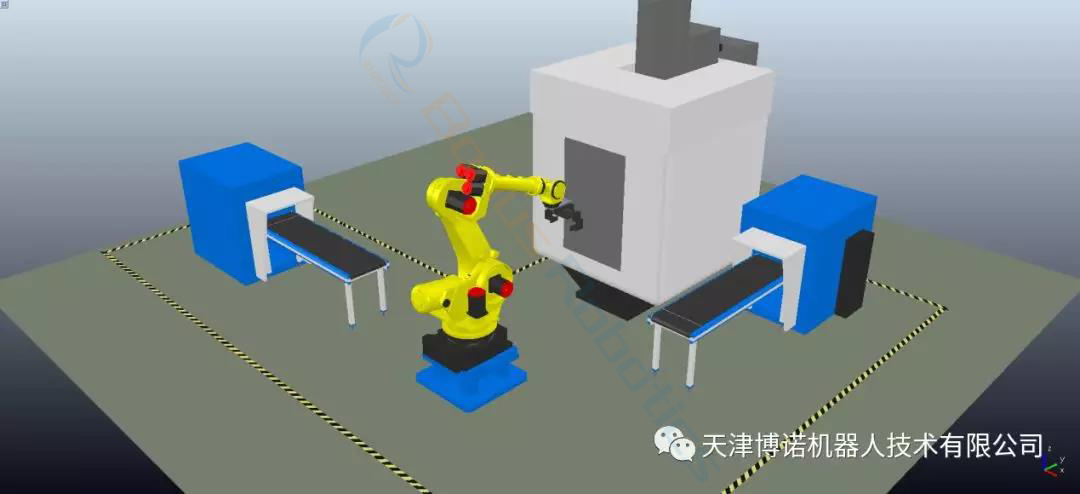

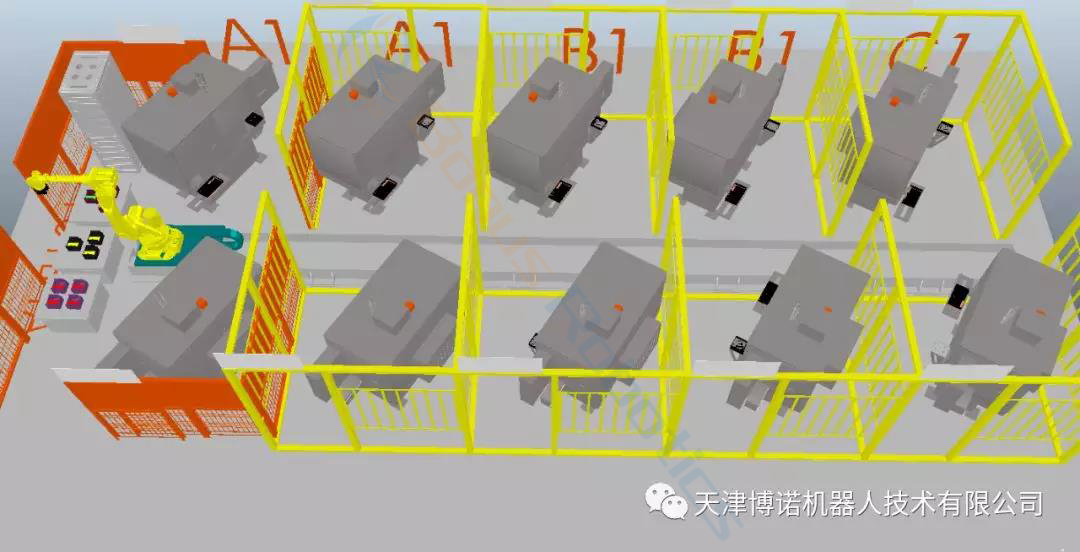

8.Manufacturing process simulation

Quickly

create a digital intelligent factory, through programming and debugging

projects, simulate the workflow and layout of industrial robots, conveying

equipment, etc.

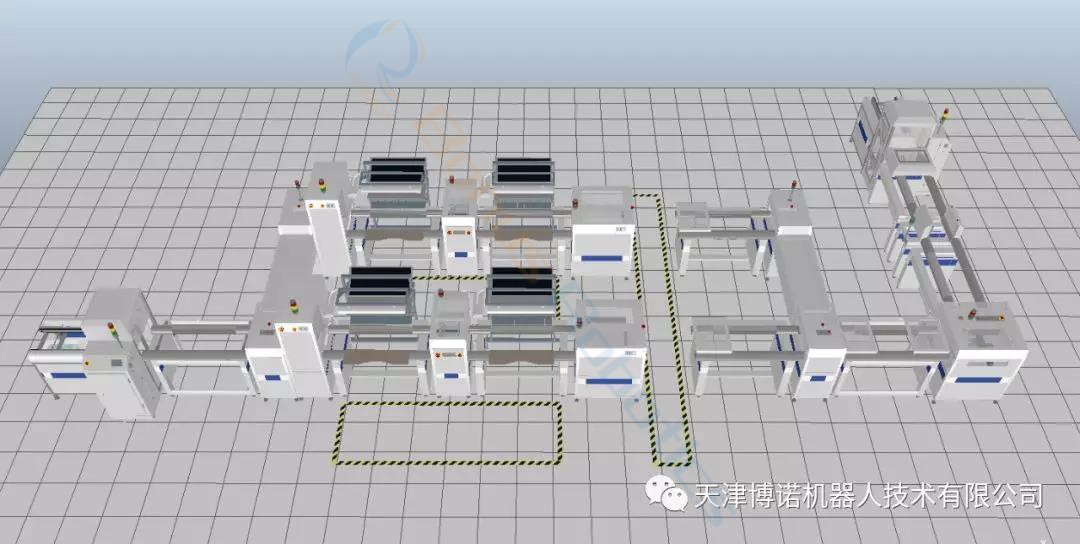

9.Intelligent manufacturing line analysis and planning

In the

conceptual design stage of an intelligent factory, the whole system can be

analyzed completely, and the mutual movement of each component can be observed

and tested. Through the system virtual simulation software to simulate the

movement and the flow of the production line in the corresponding virtual

environment, the design defects can be easily modified on the computer,

different layout schemes can be simulated, and the production line system can

be continuously improved until the optimal intelligent production line design

scheme is obtained.

10.Offline programming function

With

the help of virtual robot technology, IRobotSIM can program offline, just like

moving a real robot by your PC! With the help of various tools provided by the

software, tasks such as training, programming and optimization can be performed

without affecting production, to improve the profitability of the robot system.

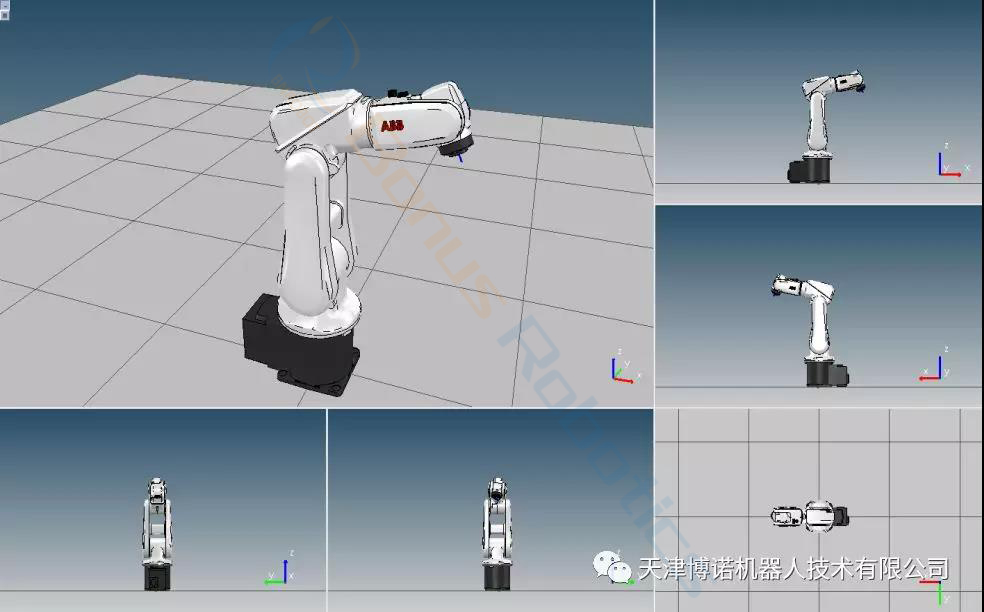

11.Multi-view function

Support

multi-view switching function, which can switch the scene to different

perspectives for operation, or select multiple perspectives to display in the

current simulation.

12.Powerful API functions

IRobotSIM uses an integrated development environment and distributed controlarchitecture. Each model can be controlled by an embedded script, plug-in, andremote client application programming interface.

IRobotSIMsupports the secondary development of C/C++, Python, Java, C#, MATLAB, Octaveand other programming languages.

13.Digital twin

It makes fulluse of IRobotSIM to import physical model, update sensor, run history, andother data, integrates multi-disciplinary, a multi physical quantity,multi-scale and multi probability simulation process, completes mapping invirtual space, to reflect the whole life cycle process of corresponding physical equipment. The virtual model of a physical entity is created digitally,and the behavior of a physical entity in the real environment is simulated bydata.

Support post output of robot motion point information; be able to directly generate code,import into the control cabinet, and control physical robots (including but notlimited to ABB, KUKA,EFORT,FANUC and other brands of robots);

The robot kinematics interface is provided. The kinematics and behavior logic of variousrobots and dynamic components can be controlled by the built-in template of thesystem or the script written in Lua language.

Supports

3-5 axis machine tools with 2 rotation axes,3-6 rotation axis series, parallel,

dual-arm, AGV trolley,Cartesian coordinates,and other robots, as well as

corresponding tooling fixtures, AGV, personnel, conveyor belts, and other

auxiliary

14.Teaching advantages of IRobotSIM

IRobotSIM

has many typical real industrial application scenarios, which enables students

to understand the workflow of an intelligent factory and complete the learning

task of intelligent work layout.

天津博诺智创机器人技术有限公司

总部地址:天津市津南区天乐创新产业园2号楼

电话:022-88825290Copyright©2016-2026,www.bonus-robot.com,All Rights Reserved;版权所有©天津博诺智创机器人技术有限公司,未经许可,严禁复制。

天津博诺智创机器人技术有限公司津ICP备17000529号-2 津ICP备17000529号-4 津ICP备17000529号-5